The development of machines and tools for woodworking

Fire Whisk

It is assumed that prehistoric, primitive man used the so-called fire whisk to make fire. This fire whisk, also called a fire drill, consisted of a round wooden stick that was turned back and forth by friction between the hands. The tip of the whisk was stuck in the hollow of another piece of wood, which contained burning material (tinder or fire sponge). The friction of wood against wood created heat that ignited the fuel.

Fiddle Drill

Prehistoric man, developing intelligence, succeeded in time to make an invention, which became of enormous importance for the development of mankind in general. In order to be able to turn the whisk, which until then had to be turned by hand, faster and more easily, prehistoric man came up with the idea of using his hunting bow to help him by looping the string of the bow once around the turning piece of drilling and then fastening it again at the other end of the bow. Drilling with this fiddle drill probably represents the first mechanical operation ever performed by mankind. For the first time, a tool was set in rotary motion not by hand, but by means of a special device. It was now possible to exert pressure on the vertically positioned drill with the hand freed by the fiddle drill and, above all, to achieve a faster rotary movement.

From the drill bit to the lathe

The principle of the lathe is contained in the drill bit, which is mounted in a drill cap (so that pressure can be applied): it was only necessary to mount the drill bit horizontally. Nevertheless, it took a long time before the lathe was built. In Egypt, for example, furniture legs and wooden vessels were still carved throughout the second millennium BC.

Turning has been known for over 3500 years, from simple woodturning to modern engineering. As early as 1500 BC, the Egyptians were using simple woodturning lathes. Wood lathes are unquestionably the oldest machines.

The industrial revolution

From about 1800, pre-industrial lathes and drills became genuine machine tools, whose tools were guided by the machine and not by man, and whose drive was based on steam power and not on muscle power or wind and water mills. Of particular importance to industrialization were lathes for the production of cylindrical objects such as axles, shafts, bolts, spindles or screws.

Corresponding machines were developed for most of the known metal-cutting manufacturing processes. Apart from lathes, these were mainly drilling machines, planing machines for the production of flat surfaces and profiles, which were driven by steam power. The milling machine, on the other hand, made a completely new process possible in the form of milling, which was suitable for tasks similar to planing.

The first use of steam as the motive power for a woodworking machine was realized almost simultaneously in the USA and England. The American engineer and factory owner Oliver Evans (1755 to 1819) combined a steam engine with a saw frame in Philadelphia in 1802. In Europe, it was a planing machine that was the first woodworking machine to be powered by steam. In 1802 it was located at the Royal Armory in Woolwich, where it was used to make gun mounts. Woolwich, then still a suburb of London, was one of the centers of English shipbuilding.

Planer for surface treatment of sawn timber in steam sawmill

England as a pioneer of industrial wood processing

The inventor of the circular saw has remained unknown to this day. However, it could be traced back to a patent by Samuel Miller dated August 5, 1777. This patent specification states, „The machine which supplies the power is a horizontal windmill ….. The upright shaft transmits its motion to a horizontal shaft. The latter has a large wheel around which runs a chain that continues over a smaller wheel. Through the smaller wheel a square iron bar passes, which carries the saws, of a circular shape … “ In England, the circular saw was already standard equipment in woodworking at the beginning of the 19th century.

Samuel Bentham (1757 to 1831), who learned the woodworking trade from scratch in the Woolwich shipyards, was the originator of countless ideas for new mechanical solutions in woodworking. Among his inventions, which numbered in the dozens, is the earliest proposal for the use of rotating cutting knives. With this he had invented the milling cutter.

The machine shop established by Bentham in London in 1792 was the first specialized factory in the world for the construction of woodworking machines. Machines for all basic woodworking operations were built there, including planing, milling, rebating, grooving, mortising and sawmills. Complicated window frames or even ornate wagon wheels were already being produced without anything resembling manual labor.

Henry Maudslay (1771 to 1831) was a mechanical engineer and one of the best metalworkers in England. He initiated the standardization of screw dimensions and made a measuring device that allowed working accuracies of 1/10000 inch, and he is considered the inventor of the support and the creator of the first self-acting lathe.

Marc Isambard Brunel (1769 to 1849), the builder of the Thames Tunnel, was probably the most important designer of sawmill machinery at that time. Born in France, he came to England in 1799 because only here was it possible to realize his bold projects.

First production plant for mass production of finished wood products in England

The first major work of joint engineering by these three pioneers of industrial wood processing was a factory for mass production of rope blocks (wooden pulleys of very different shapes and sizes) for the ships of the English navy in Portsmouth. It was built between 1803 and 1806. 43 special machines, sophisticated in every detail, including various circular saws, crown saws, mortising machines, lathes, milling and drilling machines adapted to the respective purpose, took over the shaping of the raw wood into the complicated form of the rope blocks in a multitude of interlinked work stages. Whereas 110 experienced skilled workers had previously produced 140,000 rope plungers for the British navy using hand tools, 10 unskilled workers now managed to do the same with the new machines.

Only a short time later, the three built the so-called Chatham Steam Saw in southeastern England. It was considered a model for other such projects for decades to come. Eight saw frames of all-metal construction and with steam-driven cranes and winches for transporting the logs and saw logs the „heart“ of this lumber mill.

The band saw is historically the youngest of the three classic wood sawing machines. From the first inventive conception of a „saw without end“ by W. Newberry to the suitability of this new principle of operation, nearly seventy years of development were to pass.

In 1811, the designer Charles Hamond obtained a patent for rollers as feed elements for gang saws and circular saws. However, his proposal was initially applied in practice to planing and milling machines. There soon with great success. This was because the excellent performance achieved by the then well-known „Woodworth planer“ was attributed to the roller feed mechanism.

…. and in the rest of Europe?

All other countries – with the exception of France – initially remained unaffected by this tremendous technical progress. It was not until around the middle of the 19th century that the technical achievements from England became established in the rest of Europe, and industrial wood processing with steam drive began there as well.

It was not until electricity networks were set up from 1880 that electrical energy was available to drive motors and machines were also used in the trades.

This mechanization of the craft changed the traditional way of working considerably. How and what was manufactured could be adapted to the new technology.

Tools

The development of tools took place simultaneously with the further development of machines, and tools were often their drivers.

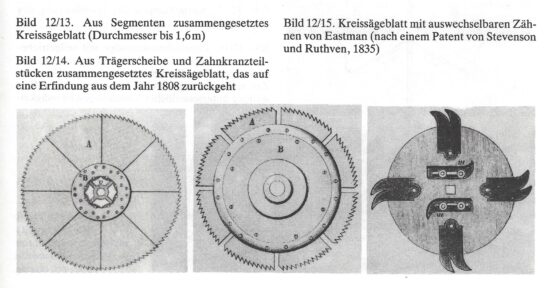

As previously described, circular saws were already standard equipment in woodworking by the 1800s. The problem with circular saws, however, was that as the diameter increased, the stability of the saw was lost. This led to ever new creative activities throughout the 19th century.

Parallel to this work, the alloys of tool steels and the methods of tool manufacture were constantly improved. In 1862, for example, the English engineer Henry Bessemer was able to present a circular saw blade, made entirely of one piece, with a diameter of 2.13 meters.

Forged drills and knives were also used as tools. For milling, wooden bases were used on which knives were fixed. There were both solid tools and cutter heads with replaceable cutting elements.

Leitz began manufacturing drills and knives in 1876, and in 1910 Leitz received the first patent for a milling tool used by machine.

Source: Historische Bilder und Texte VEB Fachbuchverlag Leipzig „Vom Steinbeil zum Sägegatter“. https://bernhard.nepelius.at/tipps-anleitungen-geschichte/geschichte-drechslerei/