The time after the Venetian gate

Chatham steam saw

At the beginning of the 19th century, the era of the Venetian frame driven by water power came to an end. The American engineer and factory owner Oliver Evans (1755 to 1819) connected a steam engine to a saw gate in Philadelphia in 1802.

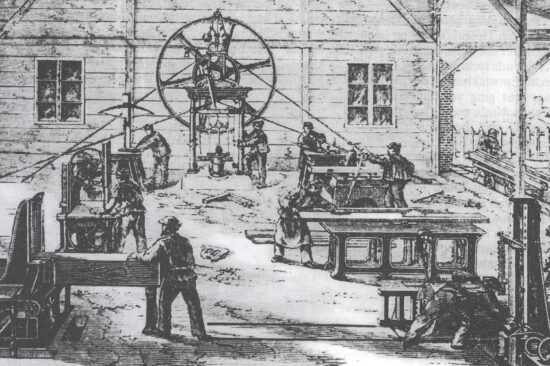

Samuel Bentham (1757 to 1831), Henry Maudslay (1771 to 1831) and Marc Isambard Brunel (1769 to 1849), who are regarded as pioneers of industrial wood processing with their factory in Portsmouth for the mass production of rope blocks, built the so-called Chatham steam saw in southeastern England in 1814. It was considered a model for other projects of this type for decades to come. Eight saw frames of all-metal construction and with steam-driven cranes and winches for transporting the logs and saw blocks were the „heart“ of this lumber factory.

The development

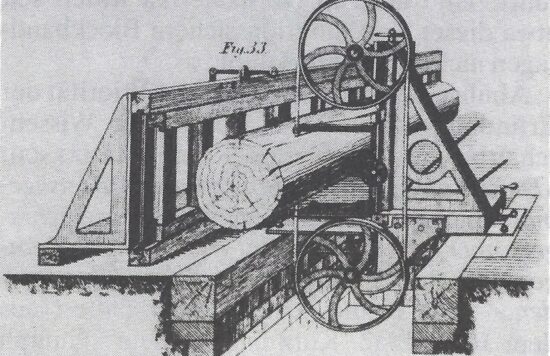

In designing their first steam saw frames, the English mechanical engineers essentially relied on solutions that had proven themselves in frame saw construction over 600 years. However, technical and design innovations soon became apparent. In the following four decades, the steam-powered full frame saw was developed to such a performance that it surpassed the wooden fret frame several times over.

The many centuries old wooden tooth drive was replaced by the belt drive. The belt pulleys were arranged on the creel main shaft together with the flywheel and the connecting rod.

The conventional block carriage drive also no longer met the requirements. The feed motion was no longer derived from the saw frame but from the creel main shaft. To transmit the motion, an eccentric disc was mounted on the shaft and connected to the push rod of the pusher.

It was only with the steam sawmills that it became possible to produce sawn timber on an industrial scale.

In the first half of the 19th century, steam saws were mainly found in England and France, and only after 1850 in the rest of Europe. After that, however, the spread was rapid.

In 1870, a factory not far from Riga employed about 600 workers to keep 10 saw gangs, five circular saws and other woodworking machines constantly busy, as well as to keep the steam engines running. The most powerful of the steam engines running in the compound had an output of no less than 250 hp.

A lumber company located in Amstetten was also one of the largest in Europe at that time. The drive shaft with a length of 45 m and a diameter of 14 cm shows the high technical standard in mechanical engineering at that time.

Steam sawmill with attached further processing around 1870. The machine equipment includes the side frame for precutting and the full frame for recutting (first processing stage) as well as a circular cut-off saw, band saw, planing machine, milling machine and scroll saw/mechanized version of the fret saw (second processing stage).

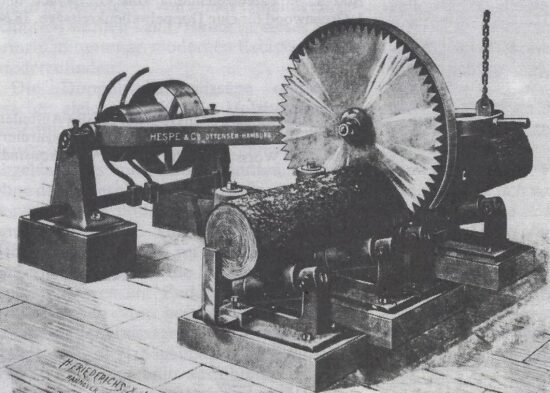

The use of circular saws

At the beginning of the 19th century, attempts were also made in England to use circular saws instead of the gang saw, but these failed. The stability of the circular saw depends on the thickness of the blade, which means that the circular saw produces larger kerfs and thus more sawdust.

However, the circular saw was very suitable for cutting logs and squared timber to length. As early as 1835, a circular saw blade with a diameter of 2.1 m was used for this purpose. With this, it was possible to cut through a log with a diameter of 0.9 m at 300 rpm in 15 seconds.

It was not until 1860 that the circular saw also found its way into the sawmills of Central European countries and only since 1880, about 100 years after its invention, has it been part of the standard equipment.

The long way to the log band saw

From the first inventive conception of a „saw without end“ in 1808 by Newberry to the suitability of this new functional principle for log cutting in the sawmill, almost seventy years of development were to be necessary.

The long period of development was due to the fact that at first there were still inadequate metallurgical possibilities in the manufacture of the endless saw blade. It was not until the right alloy and heat treatment were found that the problem of the poorly variable relationship between elasticity and cutting ability could be solved.

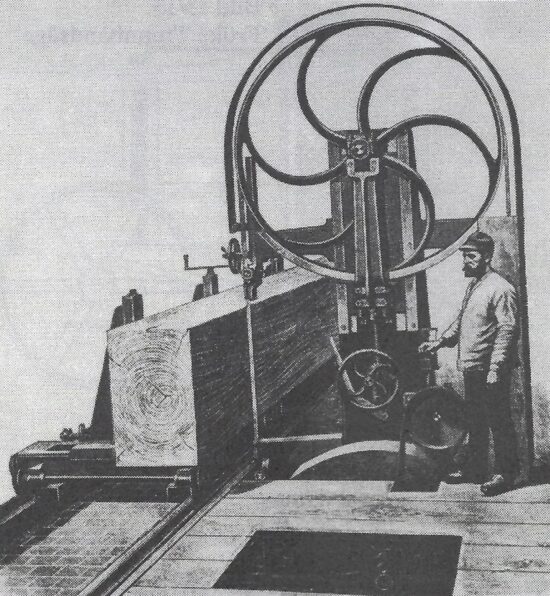

Log band saw – designed in 1862 by Bernier and Arbey

Around 1865, the technical conditions were such that the first steps from small band saws to log band saws could be taken – first in France and then in North America. It is uncertain exactly when the log band saw actually achieved satisfactory results in practice. What is known is that it was demonstrated to the public under practical conditions at the World’s Fair in Paris in 1878.

From 1880, the log band saw was increasingly used for cutting very thick and valuable hardwood logs.

Fully developed log band saw, year of manufacture 1895.

Among the largest log band saws at the end of the 19th century was a machine built in New York. Its wheels had a diameter of 1.9 m, the saw blade a length of 25 m and a width of 25 cm. Logs over 1.5 m thick could be processed. The machine managed 240 rpm and a cutting speed of almost 23 m/s.

The log band saw has weighty advantages over the full gang saw. It produces clean cut surfaces, the thickness of the lumber can be varied from cut to cut, and the clearance is such that even exceptionally thick lumber can be processed.

However, the expectation expressed by experts at the time of the log band saw’s development that this new machine would replace both the saw frame and the circular saw in the production of sawn timber was not fulfilled. On the other hand, the log band saw was given an equal place next to these two other classic sawing machines.

Source: Historische Bilder und Texte VEB Fachbuchverlag Leipzig „Vom Steinbeil zum Sägegatter“ Finsterbusch/Thiele